Sometimes businesses have great ideas. They know exactly what they need to do, what product they need to sell, how to make the product — but they’re not confident or comfortable with completing all the business processes themselves.

Maybe they’re not adept at being able to manufacture the product themselves.

That’s where Business Process Outsourcing comes in — businesses can hand over certain tasks or entire processes to an expert third-party provider, who will manage and complete the work on their behalf.

BPO providers usually specialize in a particular industry or type of process, so when manufacturing businesses look to outsource they often seek out those with experience in the sector.

After all, few things are more important than getting product out to market quickly and efficiently, without compromising on quality.

In this article, we will discuss BPO in the manufacturing industry — what it is, how it works and some of the benefits it can bring to businesses.

What Is BPO In Manufacturing?

BPO in manufacturing is the outsourcing of specific tasks or entire business processes within the manufacturing sector to a third-party provider.

These providers will have expertise and experience in completing such work, often with a focus on efficiency and quality.

The most common type of BPO in manufacturing is known as contract manufacturing, whereby businesses outsource the actual manufacturing process to a third-party.

This can be done for a number of reasons, such as businesses not having the necessary equipment or capabilities to manufacture products themselves, or wanting to free up internal resources to focus on other aspects of the business.

Whatever the reason may be, BPO in outsourcing is becoming increasingly common in the business world.

Real-life Examples of BPO in Manufacturing

Imagine a company that sells bicycles. This company has a great idea for a new type of bicycle, and they have the design ready to go.

However, they don’t actually know how to make bicycles — they only know how to sell them. So, in order to get their product to market, they need to outsource the manufacturing process to a third-party who does know how to make bicycles.

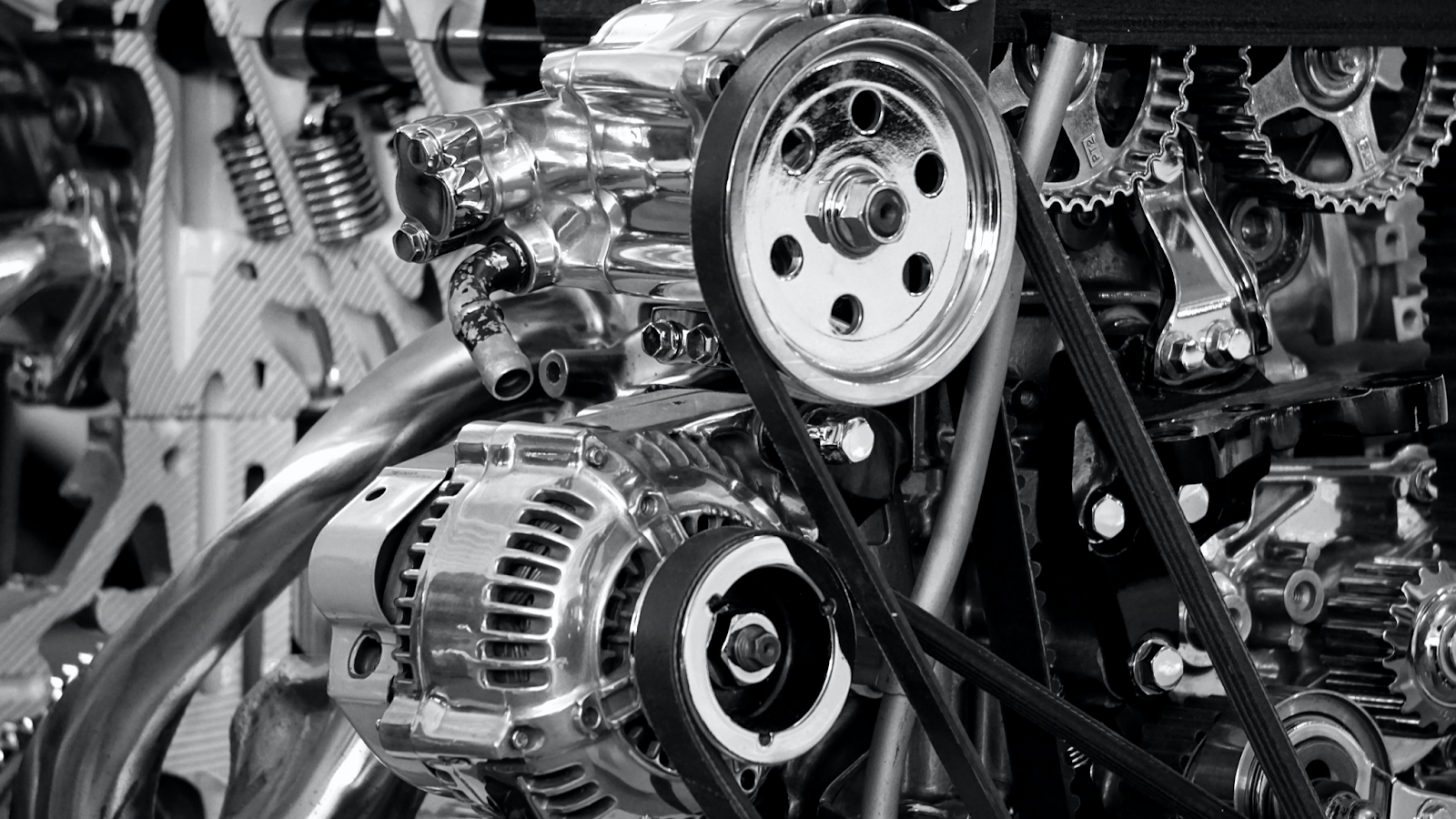

Another example might be a company that makes car parts. This company has all the necessary equipment to make car parts, but they want to free up their internal resources so that they can focus on other aspects of the business.

As a result, they might outsource the actual manufacturing of car parts to a third-party provider.

5 Benefits Of BPO In Manufacturing

There are numerous benefits that businesses can experience by outsourcing specific tasks or processes within their manufacturing operations. These include the following:

1. Cost Savings

One of the main reasons businesses choose to outsource is to save money.

Contract manufacturing can be significantly cheaper than if businesses were to produce products themselves, as providers will have economies of scale and access to bulk discounts on materials.

2. Increased Efficiency

BPO providers will often have specialist knowledge and experience in completing manufacturing tasks quickly and efficiently.

Instead of businesses wasting their time on tasks they aren’t good at, they can increase their efficiency massively by outsourcing difficult tasks.

This can lead to a significant increase in productivity for businesses, as well as freeing up internal resources which can be better used elsewhere.

3. Improved Quality

In order to compete in the market, businesses need to ensure that their products are of a high quality. By outsourcing manufacturing, businesses can benefit from the expertise and quality control procedures of experienced providers.

4. Flexibility

BPO provides businesses with greater flexibility when it comes to managing their operations.

For example, if there is a sudden increase in demand for a product, businesses can quickly scale up production by outsourcing additional work to BPO providers.

5. Risk Management

Outsourcing can help businesses to manage and mitigate risks associated with manufacturing, such as fluctuations in raw material prices or issues with suppliers.

By using a BPO provider, businesses can transfer some of these risks to the provider themselves.

How Does BPO In Manufacturing Work?

BPO providers will typically work with businesses to understand their specific requirements before putting together a proposal outlining how they can help.

Once both parties have agreed to the terms of the engagement, the BPO provider will then begin working on behalf of the business to complete the required tasks or processes.

This could involve anything from managing and coordinating suppliers, to overseeing the production process itself, right through to arranging shipment and delivery of products.

The scope of work will be agreed in advance and will be tailored to the specific needs of the business.

5 Challenges Of BPO In Manufacturing

Business isn’t all that easy. Along with its share of benefits, BPO in manufacturing offers some difficult challenges that have to be dealt with accordingly.

Let’s talk through a few of these in further detail.

1. Capacity and Lead Time Planning

One of the main challenges that businesses face when outsourcing manufacturing is ensuring that there is sufficient capacity to meet demand, whilst also maintaining acceptable lead times.

This can be difficult to achieve without over-committing or under-delivering, which can have a negative impact on customer satisfaction.

2. Quality Control

Another key challenge is ensuring that products meet the required quality standards, as any issues will likely reflect negatively on the business itself.

This has the potential to be a tough ask if there isn’t a clear and concise communication channel between the business and the BPO provider.

3. Change Management

As with any outsourcing arrangement, businesses need to be aware of the potential for change within their manufacturing processes.

This could include changes to products, suppliers or even the manufacturing process itself. Such changes need to be managed effectively in order to avoid any negative impacts on the business.

4. Contractual Agreements

Businesses will need to put in place robust contractual agreements with their BPO providers, in order to protect their interests. This includes specifying the required quality standards, lead times and delivery schedules.

5. Cost

One of the main considerations for businesses when outsourcing is cost, as they will need to ensure that there is a positive return on investment.

This can be difficult to achieve if the manufacturing process is complex or time-consuming, so it’s important to weigh up all the costs and benefits before making a decision.

Which Companies do BPO in Manufacturing?

There are many companies that offer BPO in manufacturing, with some of the most well-known being Jabil, Flextronics and Celestica.

These companies have a wealth of experience in contract manufacturing, and often work with some of the biggest names in the tech industry.

Other companies that offer BPO in manufacturing include Sanmina, Foxconn and Pegatron — all of which are based in Asia.

This is due to the fact that labor costs are often lower in Asian countries, which can be a significant saving for businesses when outsourcing manufacturing processes.

5 Alternatives to BPO in Manufacturing

If you believe that BPO might not be the ideal solution for your firm, rest assured. There are a number of alternatives to business process outsourcing, which we have discussed below:

1. In-house Manufacturing

This is where businesses choose to complete all manufacturing processes themselves, without outsourcing any work.

This can be a good option for businesses with the necessary resources and capabilities to do so, but it can be more expensive and time-consuming than BPO.

2. Joint Ventures

A joint venture is where two or more businesses come together to share resources and expertise in order to complete a project or task.

This can be useful for businesses who want to maintain control over the manufacturing process but don’t have all the necessary resources themselves.

3. Strategic Alliances

A strategic alliance is similar to a joint venture in that two or more businesses come together to share resources and expertise.

However, unlike a joint venture, an alliance is not usually focused on a specific project or task, but rather on a long-term relationship between the businesses.

4. Mergers and Acquisitions

In some cases, businesses may choose to merge with or acquire another business in order to gain access to their manufacturing resources and expertise.

For businesses that want to quickly and easily expand their manufacturing capabilities, this has the potential to be an excellent option. However it does have a few drawbacks — as it can be costly and complicated to complete successfully.

5. Make-to-order

In the make-to-order manufacturing process, businesses receive orders from customers and then manufacture the products specifically for those orders.

This is good for businesses who want more control over the manufacturing process and want to be able to tailor products to customer specifications.

Final Thoughts

Now that we’ve covered the ins and outs of BPO in the manufacturing industry, hopefully you have a better idea of what BPO entails in this particular sector.

It can be an excellent option for some firms, but if you feel the drawbacks outweigh the benefits — consider using an alternative method of outsourcing as detailed above.